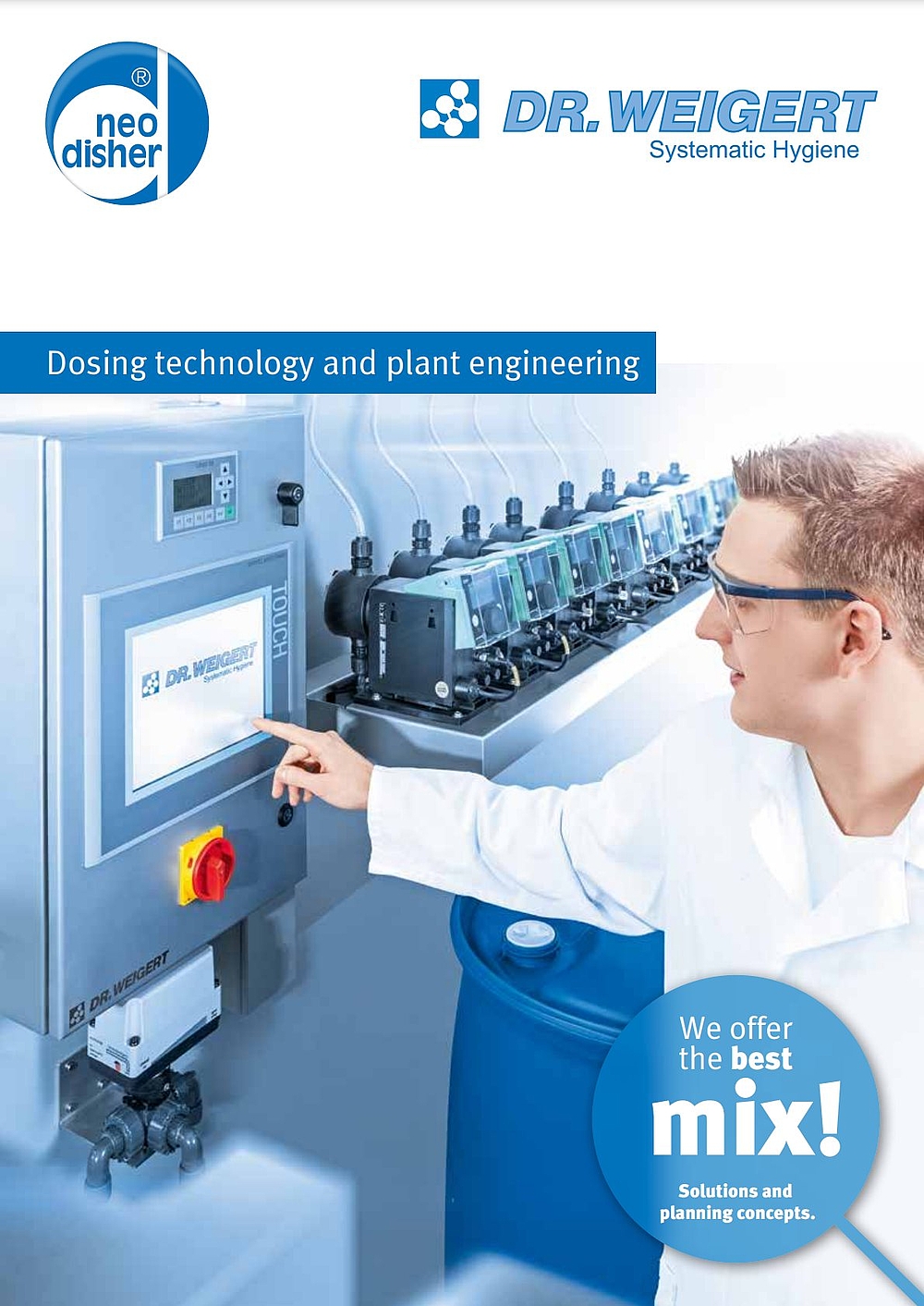

Dosing Technology

Modern dosing systems with data capture for automatically supplying and monitoring washer-disinfectors are a prerequisite for safe process management, validation and permanently optimal cleaning results in instrument reprocessing or when cleaning laboratory glassware and utensils.

Dr. Weigert offers optimal designs for:

- process-oriented analysis and weak point determination

- central and distributed systems for the metering and controlling of cleaners and disinfectants

- weigomatic DOS Manager and weigomatic Data Management for the collection and transmission of important operating and process data

- mixing equipment for preparing and spraying ready-to-use detergent and disinfectant solutions

Central dosing units supply multiple washer disinfectors (WD) with liquid process chemicals in larger washing units. The installation of the systems can take place irrespective of the location of the washer disinfector. The use of large containers makes application not only more economical, but also very user-friendly with regard to industrial safety. Awkward handling of canisters is eliminated and dosing takes place in closed systems! The modular weigomatic® principle combines individual solutions with an exceptional degree of flexibility and a wide range of retrofitting options. We will design the optimal dosing unit to suit your needs!

weigomatic data management integrates important quality aspects into the cleaning and disinfection process.

All relevant data such as running times of washer disinfectors and amounts of water and detergents/disinfectants used are continually recorded and documented via the data storage unit. This data can then be clearly displayed on a computer

or the touch panel, can be viewed and evaluated from the desktop, and analysed or assessed locally or on the Internet.

This guarantees the highest degree of efficiency and early error and fault detection – a must for all validated processes and for optimised process

reliability.

weigomatic® DOS manager is a combined dispensing and monitoring system for managing the dosage of liquid process chemicals via weigomatic® buffer tanks in washer disinfectors. The integrated memory unit permits the continuous collection of specific operational data, such as quantities used and periods of operation – which can be clearly evaluated and documented on a computer. Early fault detection ensures cost-effective operation and excellent process reliability.

The system enables automatic touchless product identification which prevents mix-ups. Therefore, the system not only ensures intuitive handling when changing product containers but first and foremost guarantees an absolutely reliable start of a successful cleaning and disinfection process. The operating principle is ingeniously simple and is based on the consistent use of RFID technology (Radio Frequency Identification).

Containers fitted with weigomatic® RFID transponder are individually coded. The transmitted signal is read by a receiver fitted on the dosing station. This ensures that the correct process chemical is used. The automatic dosing of process chemicals is activated and all quality-relevant data and parameters which are important for the cleaning process are recorded, such as e.g. time and cycle of the container exchange as well as batch number and use-by-date of the process chemical.

The new generation of the dosing system weigomatic® system ALPHA X in several variants allows the AEMP as well as endoscopies and private practices to benefit from the innovative dosing technology. Learn more about the aaplication possibilities of the weigomatic® system ALPHA X and our (highly) concentrated process chemicals in our brochure:

When it comes to the reprocessing of flexible endoscopes, space plays an important role – in smaller endoscopy departments and in registered endoscopy surgeries, lack of space is often part of everyday life. This problem was the driving force behind the design of the weigomatic® system ALPHA XS. With the weigomatic® system ALPHA XS with two process chemicals, Dr. Weigert has drastically reduced the space required in comparison with a central dosing system. At the same time, new functions have been integrated into this version of the device.

The weigomatic Drumtainer is a transportation and storage system for drums and the ideal solution for easy handling when it comes to changing and storing drums at the dosing

station, meaning a drain tub is no longer needed in the dosing room.

The drum itself remains in the weigomatic Drumtainer the whole time it is in use, and the Drumtainer is also approved as a drain tub.* Thanks to its four wheels, the weigomatic® Drumtainer is very manoeuvrable, making lifting or transferring drums a thing of the past. Storage and transportation are also easy and safe, without the need for any pallet jacks or forklifts. The tilted base enables you to use every last drop in the drum. Coloured lids prevent product mix-ups, while the external labels and safety notices also aid easy identification

Dosing technology and plant engineering - We offer the best mix!

Solutions and planning concepts

Dosing technology brochure 10.2018

(PDF - 1.253KB)

System Solutions

Our competence encompasses all elements of a hygiene concept from requirement analysis to implementation and quality assurance. Suited to your specific requirements we take care of the practice-oriented implementation.

More details